Как выбрать линолеум

Для правильного выбора линолеума важно учитывать тип помещения и предполагаемую степень нагрузки на пол (бывает низкой, средней и высокой). Затем подобрать подходящий вариант по маркировке, нанесенной на изнаночную сторону изделия.

Стандарт износостойкости линолеума EN 685

По общему европейскому стандарту износостойкости EN 685 линолеум классифицируется двумя цифрами. Первая цифра обозначает тип подходящих помещений:

2 – бытовые,

3 – коммерческие,

4 – производственные.

Вторая цифра — уровень износостойкости:

1 – пониженная,

2 – средняя,

3 – повышенная,

4 – очень высокая.

Чем интенсивнее нагрузка на пол, тем более большую вторую цифру выбирайте в маркировке.

Для жилых помещений подходит линолеум 21, 22, 23. Для зон повышенной проходимости, таких как коридоры, прихожие, кухни – 23, для зон со средней нагрузкой на пол – столовых, гостиных -22, для кладовых – 21. Для спален и лоджий - 21 или 22, в зависимости от интенсивности эксплуатации покрытий с этих помещениях.

Линолеумное покрытие с обозначениями 31, 32, 33, 34 сделано для коммерческих помещений. В офисы, кабинеты, гостиничные номера, приемные выбирайте классы 31 или 32, в зависимости от степени нагрузки. В учебные классы, бары, магазины – 33, в торговые центры, школьные коридоры, танцевальные классы, больничные коридоры – 34.

Для производственных цехов с малой нагрузкой подойдет класс 41, для складов и цехов с интенсивной нагрузкой – 42 или 43.

Как правило, чем выше класс в маркировке, тем дороже линолеум.

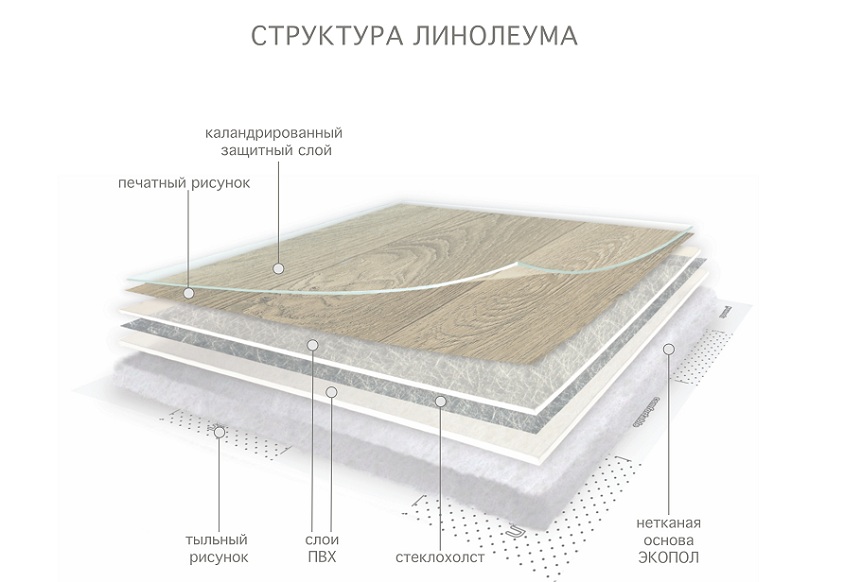

Стандарт истираемости линолеума EN 660-1

Важными критериями выбора напольного покрытия являются степень истираемости и толщина защитного слоя. Истираемость – это способность линолеума сопротивляться износу верхнего слоя, что влияет на его долговечность. Чем толще защитный слой, тем дольше он может эксплуатироваться. По устойчивости к истиранию (стандарт EN 660-1) материалы делятся на четыре группы:

- группа T - очень высокая устойчивость,

- группа P - высокая,

- группа M – средняя,

- Группа Ф – низкая устойчивость.

Коллекции линолеума Комитекс Лин относятся к группе T, с очень высокой устойчивостью к истиранию, в 2 раза превышающем стандартные значения. Это достигается благодаря использованию уникальной технологии изготовления защитного слоя Strong Wear. Каландрирование (прессование) при высоком давлении и температуре позволяет получить защитный слой более высокой плотности, чем при изготовлении методом пластизоль. Именно это обуславливает высокие показатели износостойкости и долговечности продукции ООО "Комитекс Лин".